Driveways

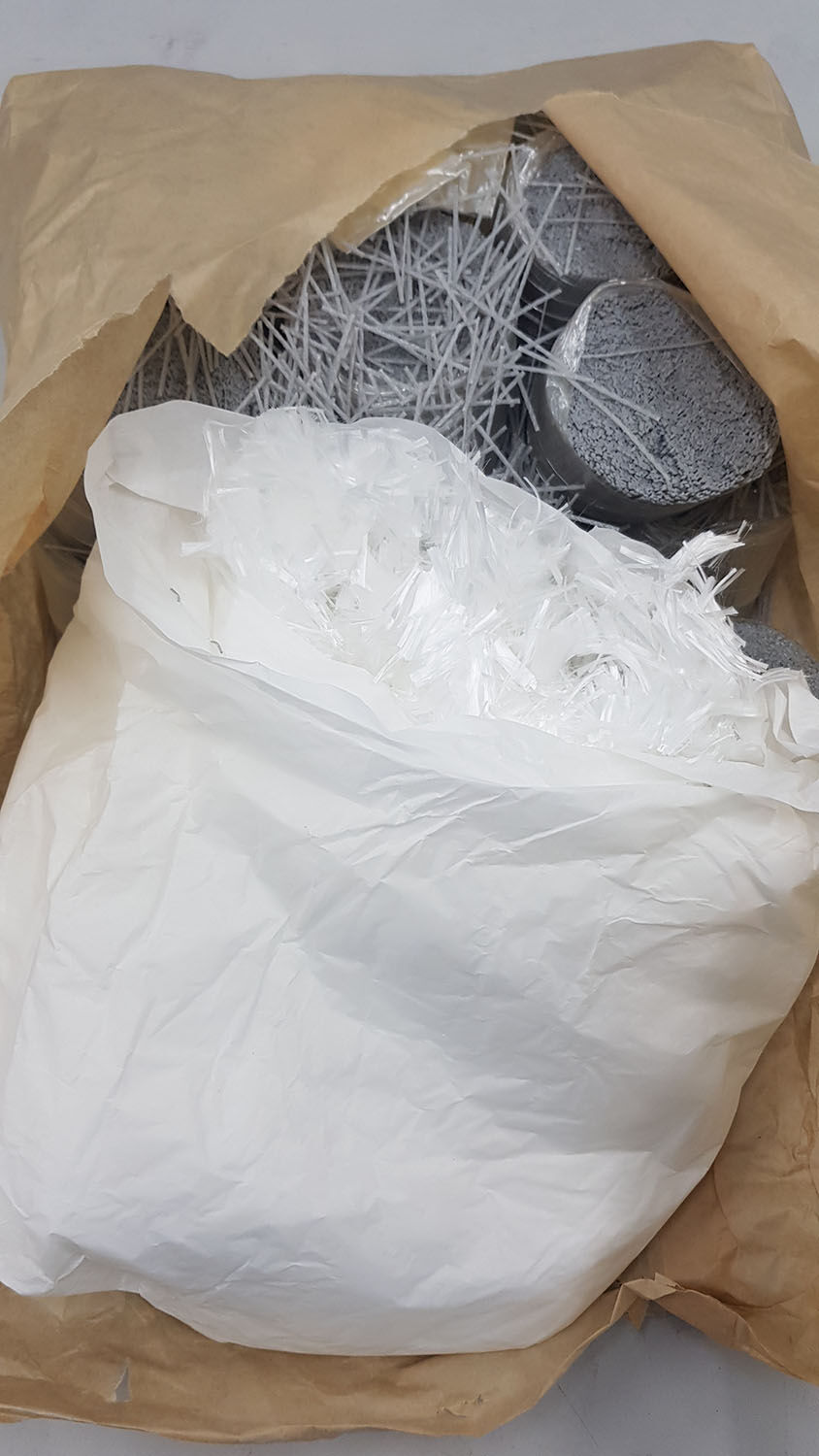

RePoly RF47 Macro Synthetic Fibre Reinforced Concrete represents a significant advancement in concrete construction.

RePoly RF47 is a suitable choice for driveways. It offers durability, safety, sustainability, circularity, and cost efficiency in construction, making it an ideal choice for creating driveways that withstand the test of time while contributing to a lower carbon, built environment.

By replacing steel mesh with Macro Synthetic fibres, driveways can be completed more efficiently, reducing labour and material costs. The crack control provided by MSFRC ensures the driveways maintain their integrity and appearance over time.

Durability and Longevity:

RF47 fibres boost concrete flexural tensile strength, resisting cracking from shrinkage, traffic loads, and weather. No steel means no corrosion (no concrete cancer). This greater durability reduces maintenance and extends concrete pavements lifespans.

Crack Control and Structural Integrity:

RF47 fibres provide superior crack control, maintaining concrete integrity, and reducing tripping hazards.

Sustainability, Environmental & Social Responsibility are Core for RePoly:

By removing the need for steel, we significantly reduce the carbon footprint of driveways. Additionally, RF47 is packaged by NDIS workers, bringing about tangible social benefits.

Ease of Installation and Cost Efficiency:

RF47 MSFRC is designed for easy installation, thereby lowering labour costs and project timelines. This efficiency also extends to long-term cost savings through reduced maintenance expenses, which helps optimize budgets.

| Comparison in 100mm Driveway |

| Item |

Traditional Mesh |

RePoly Alternative |

| Material |

SL72 Mesh |

4 kg / m3 |

| Labour |

Lay, tie and chair |

No Labour |

| Durability |

Corrosion of steel mesh |

No Corrosion |

| CO2 Footprint |

6.21 kg / m2 |

0.56 kg / m2 |

| NDIS Employment |

0 hours |

1.8 hrs / 100m2 |

MSFRC is a suitable choice for driveways, offering faster and safer construction. By replacing steel mesh with Macro Synthetic fibres, driveways can be completed more efficiently, reducing labour and material costs. The crack control provided by MSFRC ensures the driveways maintain their integrity and appearance over time.

For more information, please contact fibre@danbar.com.au